X

Oil Skimmer Price And Quantity

- 1 Piece

- 1.0 INR/Piece

Product Description

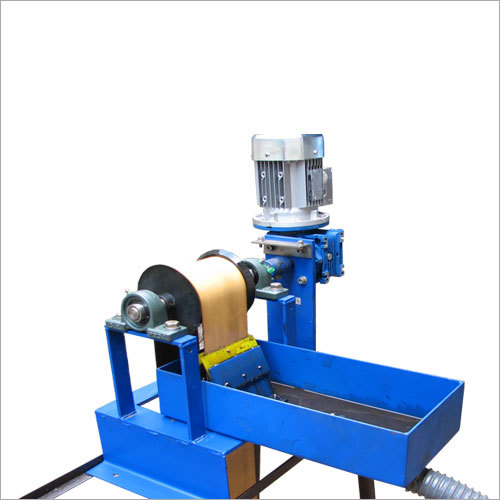

Our in-depth knowledge and industrial expertise has enabled us to emerge as a reputed manufacturer and supplier of Belt Oil Skimmer. It is an effective means of removing oil from water and water-base solutions. This system can alone will reduce oil to an acceptable level of water purity. Depending on the characteristics of the liquid, it is possible for the skimmer alone to reduce oil content to less than five parts per million in water. We manufacture this skimmer using high quality materials and components at our sound production unit. Belt Oil Skimmer can be used as a pretreatment before filtration, and in conjunction with coalescing systems.

Efficient Oil Separation for Industrial Applications

Our Oil Skimmer utilizes an endless belt mechanism that guarantees high oil removal rates, making it ideal for maintaining the cleanliness of processing coolants and water in sumps, tanks, and effluent plants. Its portable or fixed mounting options provide flexibility for a range of workspaces, while the robust construction ensures reliable operation even in demanding conditions. The corrosion-resistant design prolongs product life, delivering consistent service in harsh industrial settings.

Durable Construction and Versatile Use

Manufactured using either stainless steel or mild steel, this oil skimmer offers a choice based on application requirements and environmental demands. The surface is treated with powder coating or MS painting to enhance resistance against corrosion and wear. Designed for both new setups and existing systems, its semi-automatic operation ensures effortless maintenance and reliability, reducing downtime and enhancing overall productivity in industrial processes.

FAQs of Oil Skimmer:

Q: How does the endless belt mechanism in this oil skimmer work for oil removal?

A: The endless belt circulates through the liquid surface, attracting and collecting floating oil. As the belt moves through the skimmer, attached oil is efficiently removed by wipers or scrapers before the belt re-enters the tank, ensuring continuous oil extraction.Q: What are the installation options for this oil skimmer, and where can it be mounted?

A: This oil skimmer supports both portable and fixed installations. It can be conveniently tank-mounted or surface-mounted, making it ideal for sumps, effluent tanks, and coolant reservoirs in various industrial environments.Q: When should I use this oil skimmer in my industrial processes?

A: The oil skimmer is best used when you notice oil accumulation on coolants, in effluent tanks, or sumps. Regular use will help prevent contamination, improve process efficiency, and save on maintenance costs related to oil build-up.Q: What power connections are required for operating this oil skimmer?

A: The oil skimmer operates on standard 220V or 440V electrical supplies at 50 Hz frequency and requires an electric input of 0.18 kW, ensuring compatibility with standard industrial power sources.Q: How does the corrosion-resistant surface treatment benefit the equipment?

A: The powder-coated or MS painted surface enhances protection against rust and chemical corrosion, especially in harsh industrial and chemical environments, significantly increasing the skimmers operational lifespan.Q: Is this oil skimmer suitable for high-temperature applications?

A: Yes, this skimmer is designed to operate efficiently at temperatures up to 80C, making it suitable for a wide range of industrial fluid handling scenarios.Q: What is the typical oil removal rate and how does it benefit my facility?

A: The device removes up to 100 litres of oil per hour. This high rate supports effective separation of oil from water or coolant, leading to cleaner fluids, decreased equipment wear, and reduced environmental impact.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Sump Cleaner for CNC/VMC ' category

|

OILMAX SYSTEMS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |